Carbon Steel Catalog

Hot rolled products

It has good mechanical properties and welding properties, good toughness and elongation, and the product has a wide range of applications.

High-toughness crack-arrest wear-resistant steel NM400Tuf-NM500Tuf is the latest upgraded product in the series of traditional wear-resistant steel. While ensuring the same strength and hardness as products of the same level, it greatly improves the impact toughness and can effectively inhibit the cracking and crack propagation of steel plates.

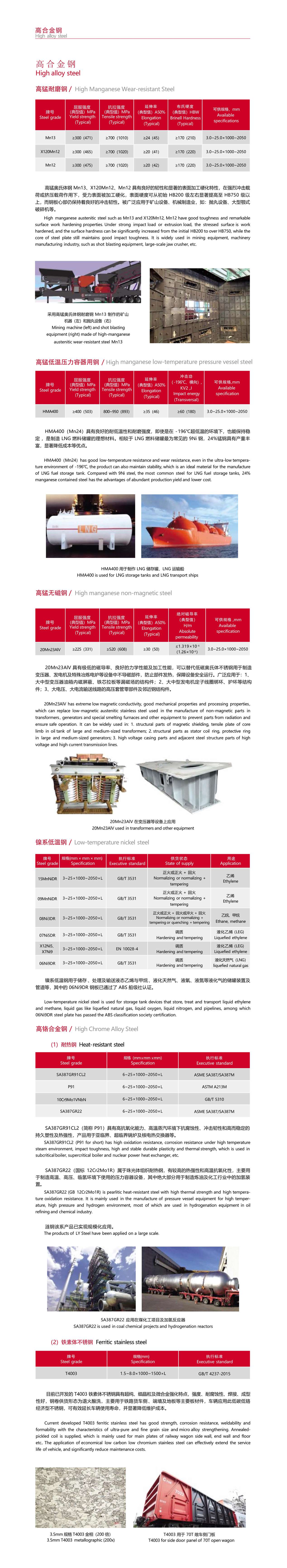

20Mn23AlV has extremely low magnetic permeability, good mechanical properties and processing performance. It can replace low-magnetic austenitic stainless steel in the manufacture of non-magnetic components in equipment such as transformers, generators and special smelting furnaces, preventing components from heating and ensuring safe operation of the equipment.

Medium- and high-carbon steel (0.20-1.2% C) is available in a wide range of grades and specifications, featuring excellent toughness, high hardenability, and high wear resistance. It is widely used in saw blades (for stone, metallurgy, woodworking, etc.), automotive parts (diaphragm springs, safety buckles, seats, gears, etc.), knives, tools, and high-strength strapping. Steel strapping thickness ranges from 1.5 to 20 mm, and widths range from 980 to 2050 mm.

The product series has a yield strength of 460~1400MPa and a thickness range of 2.0~25.4mm. It features high strength, good formability, excellent surface quality, high thickness accuracy, and good weldability. It is widely used in equipment required by machinery, coal, transportation, mining, and various engineering construction departments.

This series of products can be divided into B, X42, X46, X52, X56, X60, X65, X70, X80 and X90 steel grades according to strength level; can be divided into straight seam submerged arc welded pipe (LSAW), straight seam electric resistance welded pipe (ERW) and spiral submerged arc welded pipe (SSAW) according to pipe manufacturing welding process; and can be divided into pipeline steels for oil pipelines, natural gas pipelines, sour environment service and marine environment service according to the medium and environment used.

Bridge steel has high strength and toughness, and can withstand the loads and impacts of locomotives and vehicles. It has good fatigue resistance, certain low-temperature toughness and atmospheric corrosion resistance. The surface quality requirements of steel are high. The company can provide Q345~Q460 strength grade bridge and weather-resistant bridge steel, and can supply according to national standards, industry standards, Japanese standards, American standards, European standards or technical agreements.

The steels that Ruixiang can produce for pressure vessels mainly include steel for welded gas cylinders, steel for medium and normal temperature pressure vessels, and steel for low temperature pressure vessels.

Ruixiang has been producing steel products for ships and oceans since 2010. It holds qualifications from five classification societies: CCS, ABS, LR, BV and DNV. Its products have good mechanics, welding properties, low internal stress and dimensional accuracy.

The automotive frame series products are mainly used for longitudinal beams and cross beams of automobiles. The current market volume has reached more than one million tons. The products have good cold working formability and can meet various processing requirements such as shearing, longitudinal slitting, stamping, bending, roll welding, etc.

It mainly includes acid-resistant series and atmospheric corrosion-resistant series. It has created a big data chain based on the entire process of design-testing-service, driving the development and engineering application of high-quality corrosion-resistant steel through massive data.

Cold-rolled products

Hot-dip galvanized products are available in thicknesses of 0.3-2.5mm and widths of 900-1580mm. Available zinc coating weights range from 60g/m² to 300g/m² on both sides. The coating type is pure zinc, and either uniform or differential thickness can be achieved. Conventional product surfaces are smooth and free of spangles. Surface treatment options include oiling, chromate passivation, trivalent chromium passivation, chromium-free passivation, and chromium-free fingerprint resistance.

Cold-rolled medium and high carbon steel has good surface quality, punching performance and hardenability, and is widely used in automotive parts, saw blades, knives, tools, chains and other fields.

Cold-rolled ultra-low carbon and IF steels can be divided into five grades based on their intended use: general use, stamping, deep drawing, extra-deep drawing, and ultra-deep drawing. Ruixiang’s cold-rolled ultra-low carbon and IF steels for stamping offer excellent stamping, welding, and paintability, and are widely used in the manufacture of high-quality, complex-formed automotive parts, such as exterior and interior panels.

Cold-rolled weathering steel includes both conventional atmospheric corrosion-resistant steel and steel resistant to acidic environments. By adding corrosion-resistant elements such as Cu, Cr, and Sb, it possesses excellent corrosion resistance, extending its service life 2-4 times longer than that of ordinary low-carbon steel in outdoor service environments. It is suitable for applications such as desulfurization and denitrification heat exchangers, outdoor steel structures, and architectural decoration.

Cold-rolled welded pipe steel currently comes in two grades: ultra-low carbon and low carbon. It features excellent drawing properties, composition stability, and superior thickness precision. It can be used to produce single-layer and double-layer welded pipes and is widely used in refrigerator condenser tubes and automotive oil line pipes.

Silicon steel

Ruixiang’s non-oriented electrical steel products have the advantages of multiple states (hot coil, pickling, chilled, finished products), excellent magnetic properties, good surface quality, and timely delivery. They are widely used in compressors, small and medium-sized micro motors, high-efficiency motors and other fields.

We can supply common grain-oriented silicon steel hot-rolled/pickled/chilled coil raw materials and high magnetic induction grain-oriented silicon steel hot-rolled coil raw materials. The main grades are LGQX-6 and LGQX-1. We can also customize production according to customer requirements. The surface and edge quality, as well as the thickness accuracy of the chilled coil are excellent. They are widely used in various types of transformers, large motors, reactors, etc.

Rebar

The product has high strength and good tensile strength, and is used in many large engineering projects, such as the Wuhan-Guangzhou High-Speed Railway, the Shanghai-Kunming High-Speed Railway, the Xiangxi Aizhai Bridge, the Gezhouba Water Conservancy Project on the Yangtze River, the Philippines Metro Project, the Xiaolangdi Water Conservancy Project on the Yellow River, and the Capital International Airport.